Gain visibility into your inventory to improve supply chain resiliency

An accurate view of your inventory is key to many decisions that you make as a company, but it is more and more challenging to get timely, correct data drawn from storage locations, sales channels, and a variety of source data systems. Visibility into your inventory is the basis for replenishment decisions, your fulfillment strategy, and even the financial status of the company, yet nearly every activity related to your supply chain can affect inventory at some point.

One of the goals of inventory management is to maintain a flexible stock level and good turnover ratio, but disruptive situations in the supply chain, coupled with delayed or inaccurate data, make forecasting a nightmare.

Perhaps this is why supply chain professionals overwhelmingly plan to invest in agility and resiliency for their supply chains. A 2021 Gartner study about “responding to a disrupted world” found that 89% want to make their supply chains more agile and 87% want more resiliency.

To address these concerns, Microsoft now offers the Inventory Visibility Add-in as part of Microsoft Dynamics 365 Supply Chain Management.

Solution to inventory pain points

The Inventory Visibility Add-in can help you transform your supply chain by tackling your inventory pain points. Inventory Visibility is a highly scalable microservice that can be enabled as an add-in to Dynamics 365 Supply Chain Management and integrate with data sources from Microsoft or third-party logistics providers (3PL). It enables real-time global inventory visibility without the need to do a full-fledged enterprise resource planning (ERP) implementation.

High-volume retailers and manufacturers can easily handle millions of transactions per minute and accurately determine cross-channel inventory.

Inventory currency enables a faster response

For most businesses, it is essential to make decisions based on current, accurate data. Tracking inventory is especially important. Changes in inventory might suggest an understock or overstock situation that demands a fast reaction. Inventory Visibility lets you explore the immediate physical status of inventory, including a status of in-transit, on hand, ordered, or a custom status. This allows the organization to adjust production or sales plans in time.

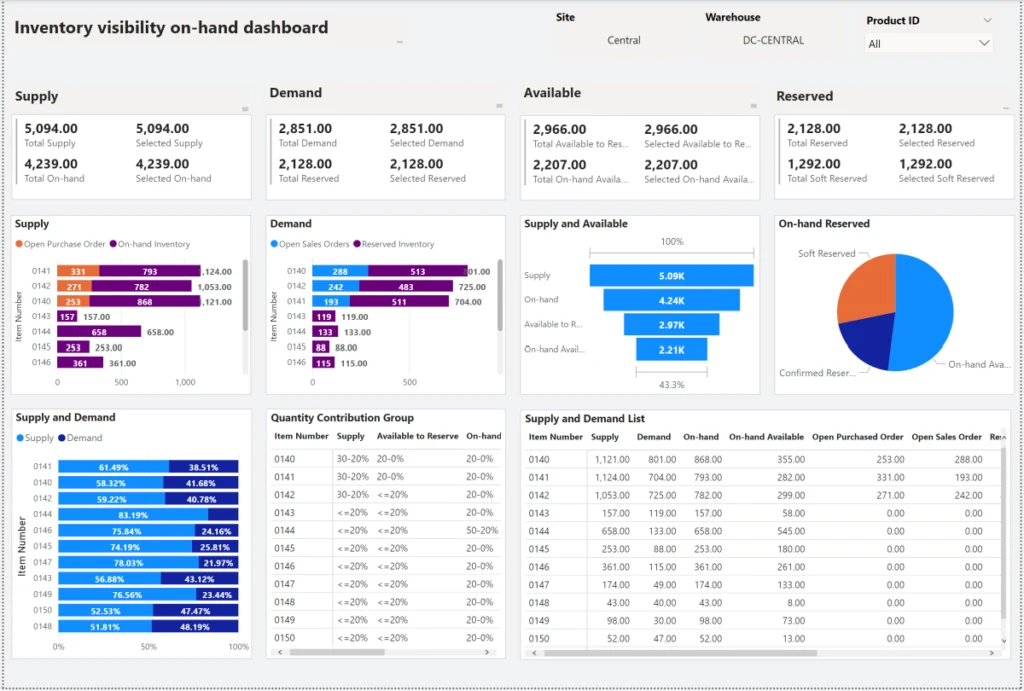

The following shows an Inventory Visibility dashboard with on-hand inventory as well as the supply, demand, and reserved inventory statuses.

Scaling to support resiliency

One way to increase resiliency in your supply chain is to adopt multiple sales channels and storage locations. The combination of online, call center, and in-store sales channels helps companies maximize sales opportunities. Setting up more storage locations, including ones closer to local markets, can better support shipping and fulfillment, especially when disruptions occur.

But companies also find that those new sales channels and expanded storage locations can have different systems, making it difficult to consolidate data for real-time information about stock level and supply and demand. Having that information is crucial to support business operations. Inventory Visibility was designed for this scenario; it is capable of handling millions of transactions across different channels and geographies in seconds.

Another strategy that supply chain executives pursue to gain resiliency is to diversify their vendor sourcing. We have heard from more customers who would like to have a view into their vendors’ inventory. This can support the sell-through or direct sales scenarios or provide better insight about potentially accessible inventory. Such companies want to integrate with the inventory systems of their vendors, and this use case is also supported by Inventory Visibility.

One of our customers, a beverage giant, uses Inventory Visibility to calculate in real time the consumption of the bill of materials (BOM) for every unit of their beverage sold in every store before the sales records are synced into their ERP system. This supports better planning and accurate cost calculations based on real-time consumption of their stock.

Previously, the inventory update process was time-consuming as data was consolidated from several thousand stores and across regions. Now, instead of dealing with inventory latency, all inventory changes can be reflected in seconds. Store operations and channel orders are much more efficient.

Next steps

If your organization is on the journey to transition from siloed systems to a unified and transparent inventory platform, consider taking the next step with Inventory Visibility.

- Existing Dynamics 365 Supply Chain Management customers can enable Inventory Visibility as a free add-in by simply following the installation instructions. Reach out to the Inventory Visibility product team by email for any installation issues.

- Get an overview of the Inventory Visibility Add-in by reading the documentation.

- If you are a potential customer or partner and want to learn more, contact the Inventory Visibility product team directly by email.

- Interested in the bigger picture? Read this blog post about how Dynamics 365 helps build the retail supply chain of the future.