Intelligent Operations: Reimagining Manufacturing One Customer at a Time

Deloitte and the Manufacturing Institute just published a new forecast that the US skills gap in manufacturing will grow to 2 million workers by 2025. It was a sobering backdrop to the opening day of Convergence 2015 where we discussed the key imperatives for manufacturing, with fresh optimism that by challenging current business models, and reimagining productivity in a new era of ‘systems of intelligence’, Manufacturers can use smart connected products and predictive systems to digitally transform their end-to-end operations, creating entirely new, and more profitable customer experiences

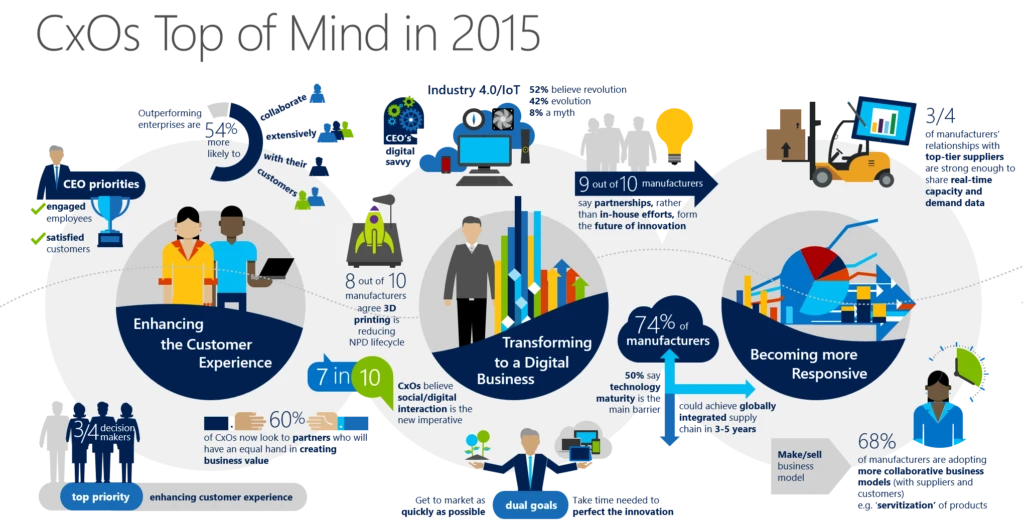

Distilled from research and ongoing conversations with CXOs, in an infographic and less than 750 words in a blog, here is our basis for reimagining manufacturing!

Digital convergence is creating opportunities to intelligently engage customers. What is old to manufacturers has become new to consumers. Digital technologies such as Industry 4.0 (also referred to as “Smart Manufacturing”or the “Industrial Internet of Things”), Additive Manufacturing (known in popular press as “3D Printing”) and smart consumer products (the “Internet of Things”), are garnering vast amounts of buyer attention. This consumer awakening creates opportunities for manufacturers to take a leap forward in margins and differentiation through rapid prototyping, agile manufacturing, and servitization of product-centric business models. Manufacturers can market smarter with new insights gained listening to smart connected products and social sentiment, blended with data from customer touch points across the marketing, sales and service channels they want to use – whether digital or not. Engineering and marketing can reduce risk and rapidly validate new product ideas with 3D models and 3D printed prototypes, confident in their digital supply chain’s ability to fulfill demand using intelligent automation and digital manufacturing.

Customer experiences are becoming the primary differentiator. By focusing on delivering great customer experiences that they will want to share, manufacturers can create sustainable relationships. They are able to sell highly ‘customerized’ products, using market and consumer insights, and validated with 3D models and 3D printed prototypes, through the ‘design win’ or ‘configure, price, quote’ process. After effectively selling ‘customerized’ products, great proactive service experiences engender loyalty in customers who then re-engage with the manufacturer when it is time to consider their next purchase.

Intelligent Operations are needed to deliver on customer promises. Delivering consistently on brand, sales and services promises entails alignment of both digital customer experiences and digital operations excellence. Everyone in your organization, from sales people and service representatives, to engineers, production/warehouse workers and delivery drivers, need to put the customer first in every decision. Building teams around the customer journey means breaking down the walls of the traditional workplace; helping employees to do their best work with connected technologies; and empowering the front line with direct access to information and tools. Dynamic business systems must connect front-office and back-office processes, be easy to to deploy, intuitive to use, and intelligently predict customer behavior and needs, to help manufacturers talent and experience starved workforce deliver personalized and proactive experiences.

Here are just 3 of the technologies Microsoft announced at Convergence 2015 for the new era of systems of intelligence, and the digital transformation of manufacturing:

- Intelligent Customer Engagement: The Spring ’15 release of Microsoft Dynamics CRM that takes intelligent customer engagement to the next level by delivering enhancements and innovations in five key areas: Productivity, Social, Mobility, Analytics, and Knowledge.

- Azure IoT Suite: With the Azure IoT Suite, we’re bringing together a variety of Azure services to help our customers, including industrial automation leader Rockwell Automation, accelerate their transformation to digital businesses using smart connected products.

- Office Delve as a prime example of how Microsoft is reimagining productivity to help people work in new and more connected ways. Delve is an experience within Office 365 that surfaces relevant content and insights tailored to each person. It is powered by the Office Graph, an intelligent fabric that applies machine learning to map the connections between people, content and interactions that occur across Office 365.

Its been a great start to Convergence 2015. The manufacturing team at Microsoft will be sharing more of our vision for intelligent customer engagement and intelligent operations in coming weeks as we prepare for Hannover Messe 2015.