How to produce an item at time of sales order if there is residual balance of the finished goods

I had published a blog post earlier this month which covered the process of how to produce an item at time of sales order. In this post I will cover another scenario where there is residual stock of bagged item in the warehouse, and there is a requirement to produce the difference from a production order. This could be handled by Net requirement functionality from the sales order line, which will fire a planned production order by the difference. After firming the planned production order the system will create a production order to produce the quantity.

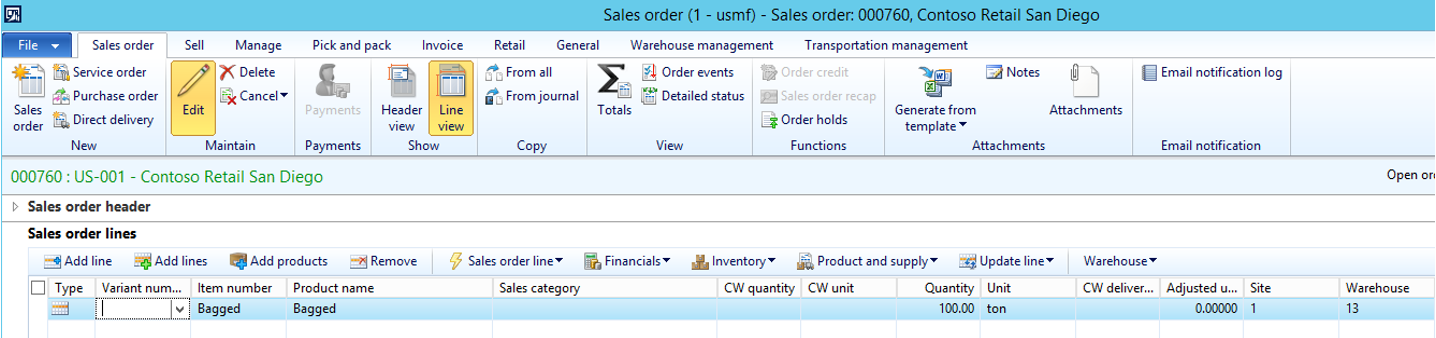

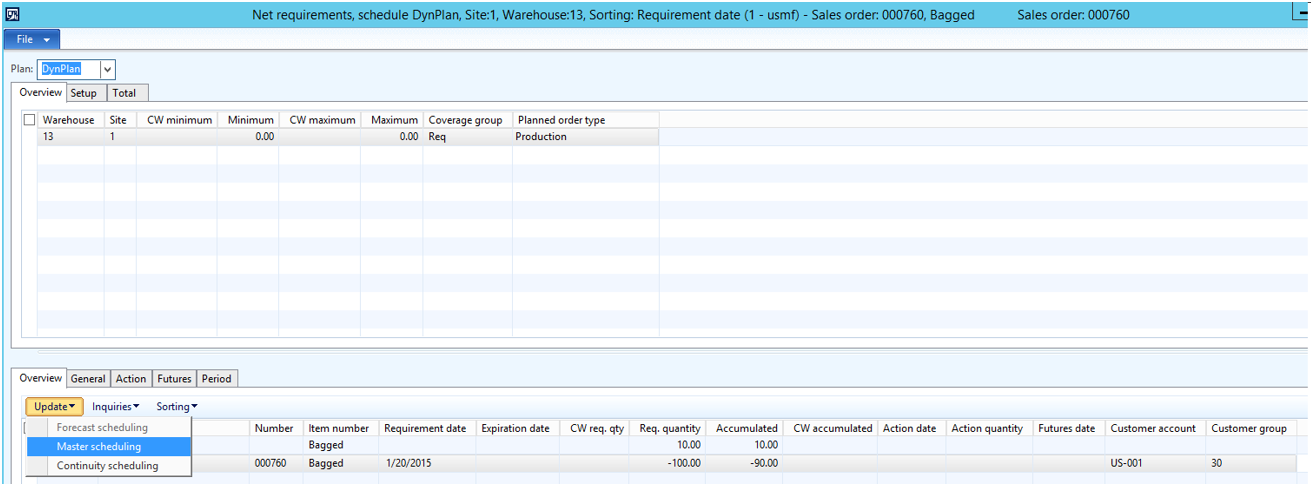

The on-hand shows that the bagged item has physical inventory = 10 and the on order = 100 that is entered in a sales order line.

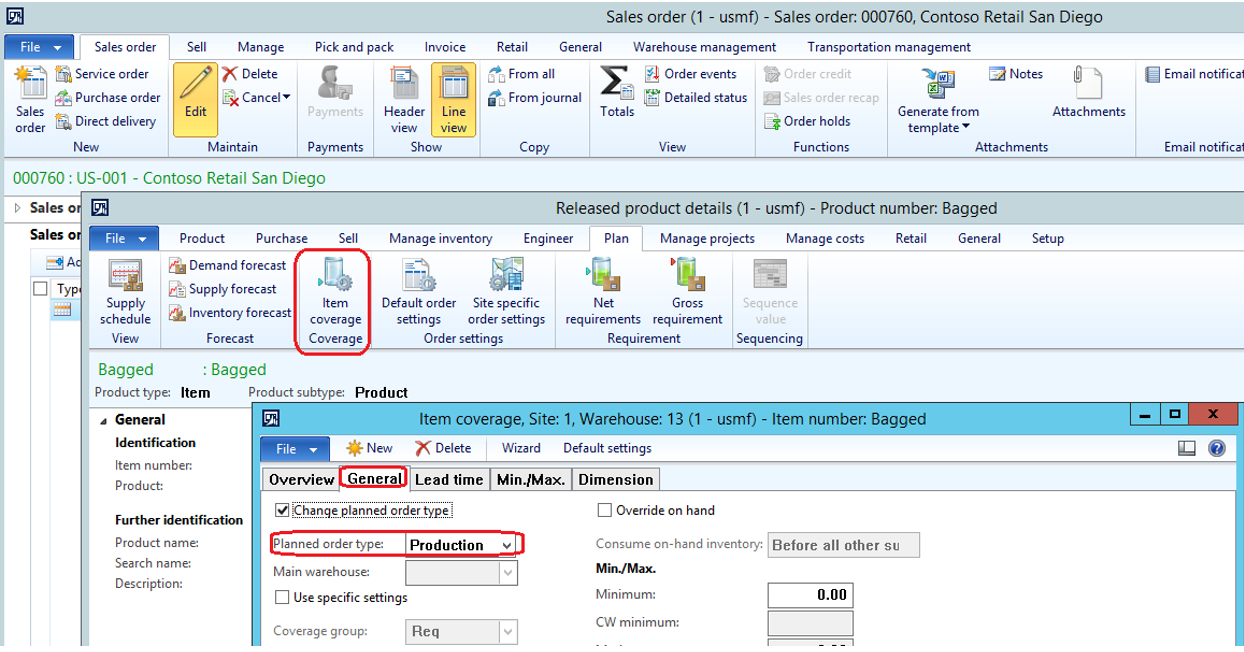

Ensure that there is a coverage group on the item setup, with planned order type Production.

Sales order with 100 ton.

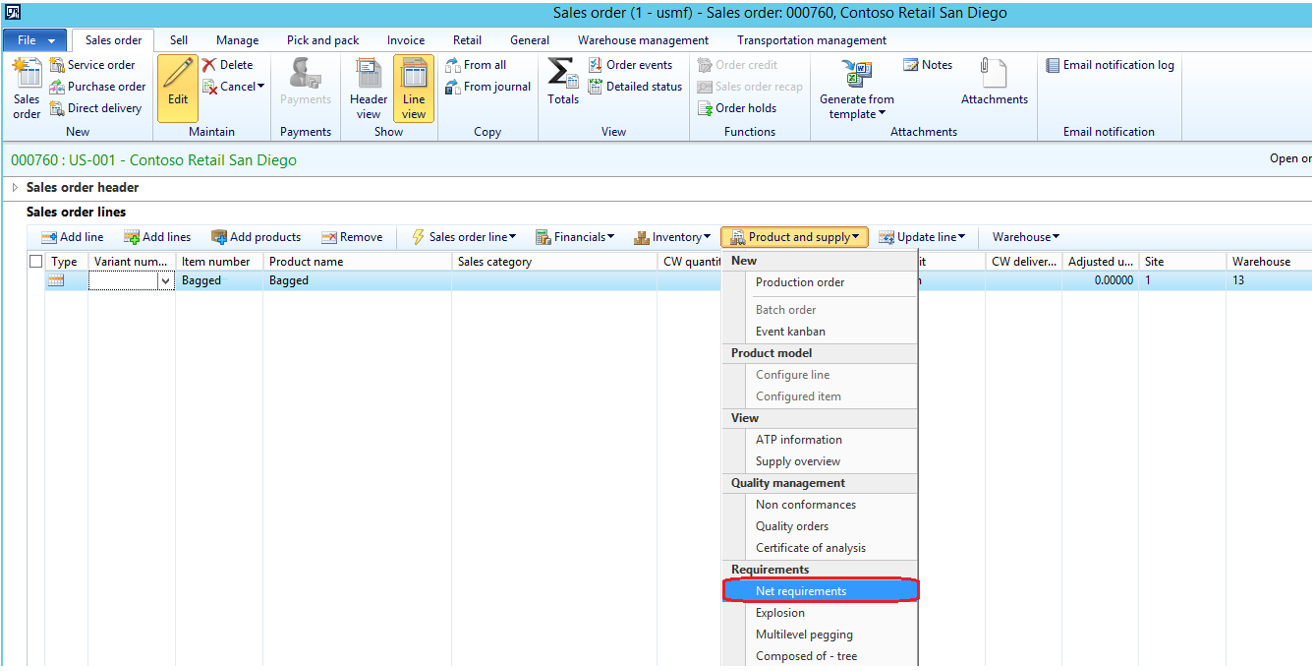

Then go to Product and Supply, and select Net requirement.

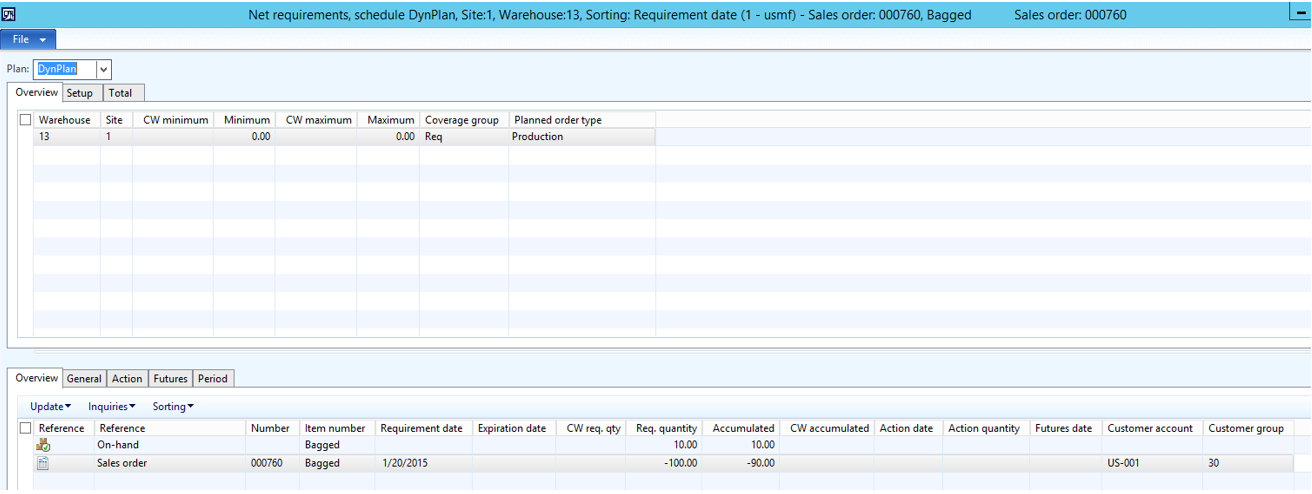

Net requirement form

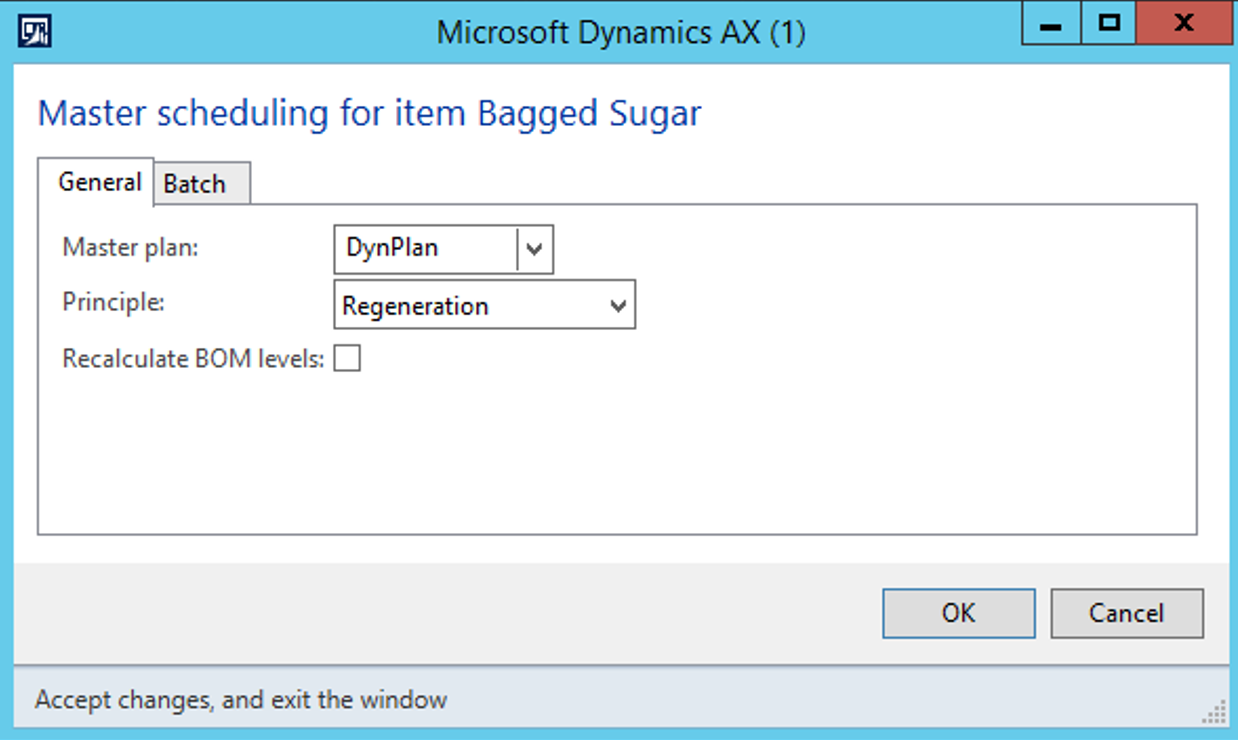

In the lower pane select Update| Master scheduling

Press OK

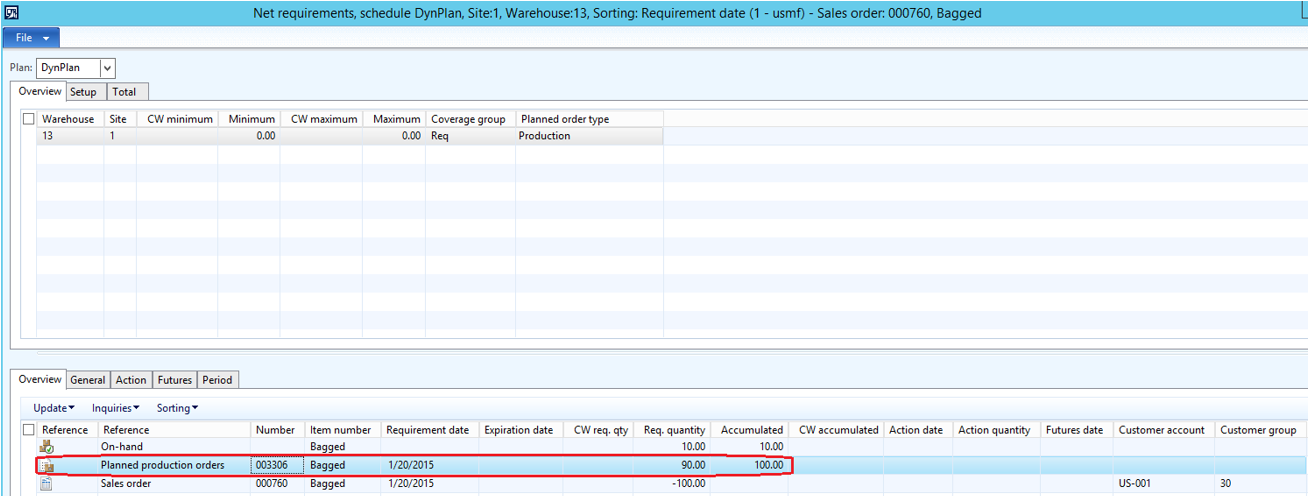

A planned production order will be created, and you can see the line on the net requirement

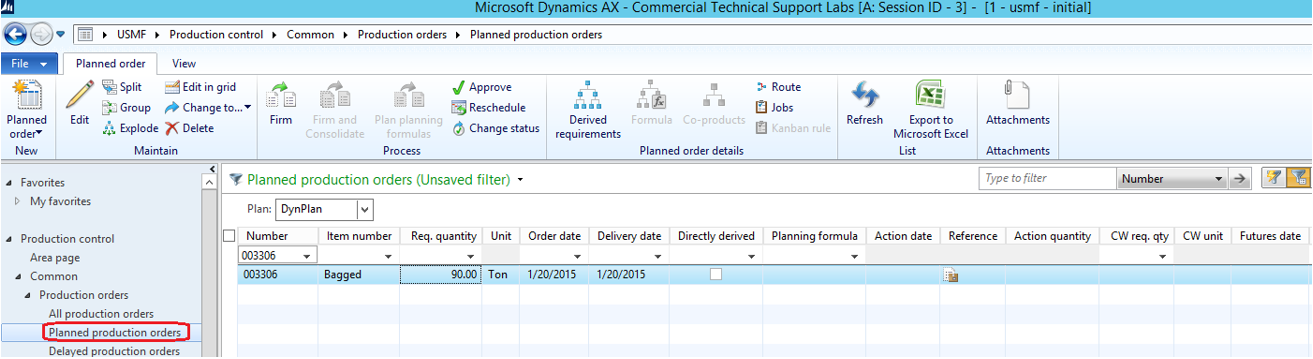

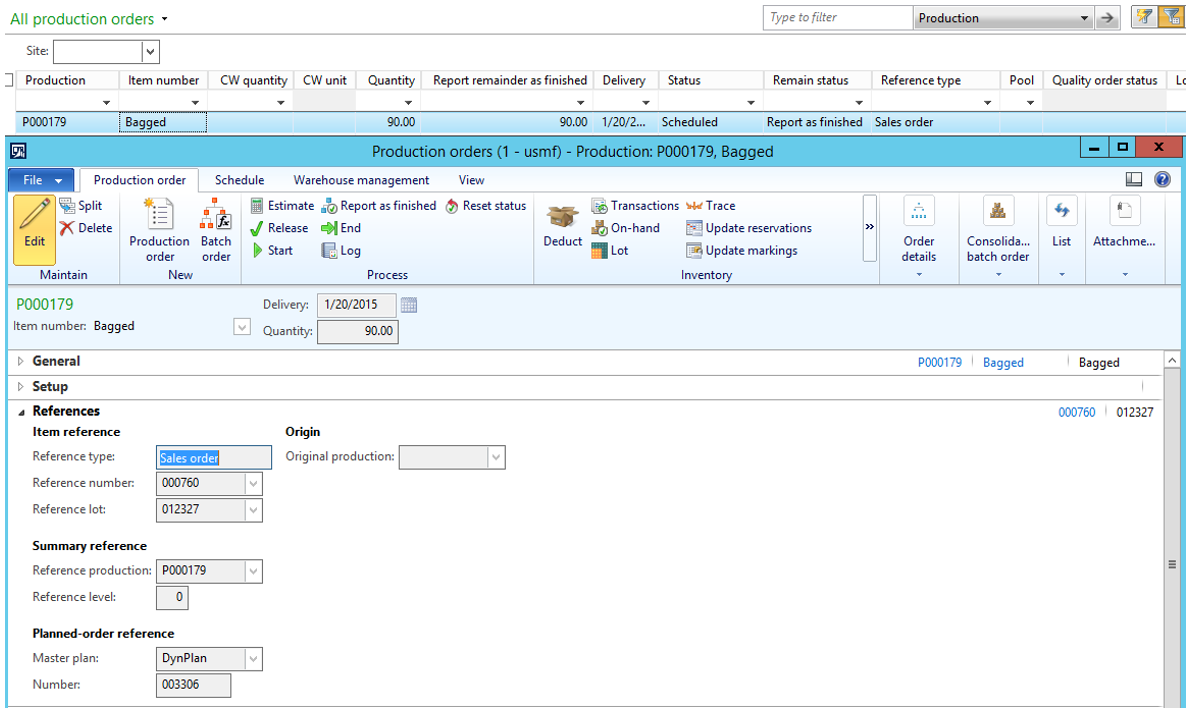

In order to Firm the planned production order, go to Production control| Common| Planned production order Ensure you filter on the same plan “DynPlan in my example”