Cross-docking product packages in AX2012 R3 CU8 Part 2 Process Flow

AX2012 R3 CU8 introduced exciting new cross-docking functionality for product packages. This first part of this article described the setups that must be in place for cross-docking. This article describes the end-to-end process from creation of a purchase order through to shipping of the transfer orders.

Cross-docking Process

The process begins with the creation of a purchase order for product packages. The transfer orders to distribute these packages to other warehouses are then created, and the cross-docking packing structure is defined.

The goods are received into the warehouse on the parent LP, and put in the cross-dock location. The operator uses the LP packing menu option on the mobile device to assign a LP to each individual package, based on the information in the packing structure.

The transfer orders can then be released for picking, picked from the cross-docking location and shipped.

Create a purchase order

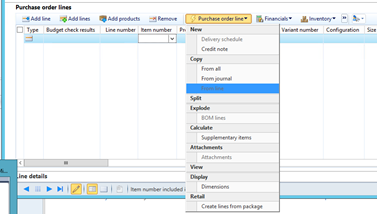

The cross-docking process starts with the creation of a purchase order. The packages in the demo data are purchased from vendor 1001, so we select this vendor. On the Purchase order line menu, there is an option to Create lines from packages.

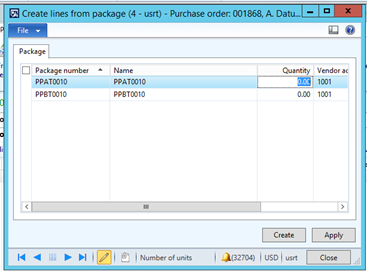

This option displays the available packages, and allows you to select the quantities of each.

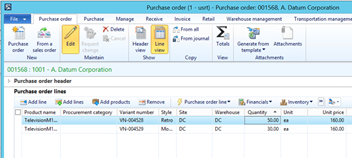

In the screenshot below, a quantity of 10 of the 2nd package in the demo data has been specified and order lines have been automatically created for 50 Retro style and 30 modern style TVs.

Create the cross-docking transfer orders

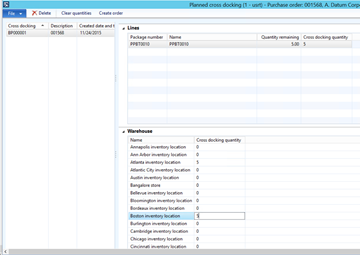

The next step is to define the quantity of packages to be sent to each receiving warehouse and to create the transfer orders. On the Retail tab of the Purchase order, the Functions > Cross docking packages menu option displays the screen below, where that information can be entered. In the example below, I have allocated 5 of the 10 packages ordered to the Atlanta store and the remaining 5 to the Boston store.

Once the quantities have been specified, the option to ‘Create orders’ creates the transfer orders.

Create the packing structure

The cross-docking packing structure must now be created. This structure is similar to that of an ASN received from a vendor. The structure is created from the Load planning workbench (Located under Warehouse management > Common > Waves > Load planning workbench). The purchase order should first be added to a load. The menu option ‘Create cross-docking packing structure’ on the ‘Ship and receive’ menu can then be used to generate the packing structure. Once the packing structure has been created, the ‘Packing structure’ menu option can be used to view it.

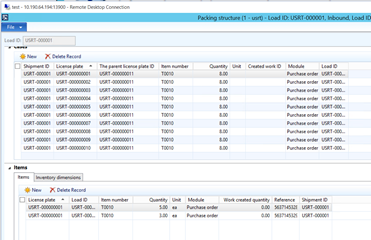

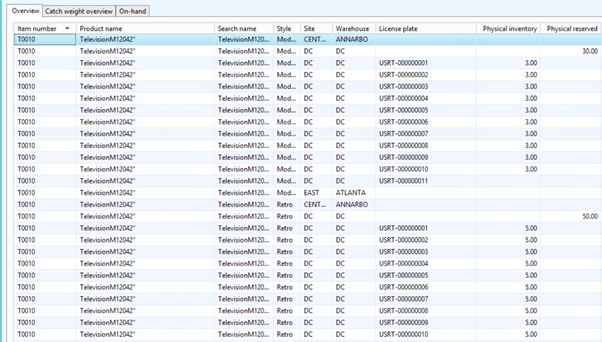

The screenshot below shows the packing structure for my purchase order. A license plate (USRT-000000001 to USRT-000000010) has been created for each package and a parent license plate (USRT-000000011) has been assigned to the whole shipment.

Receive the goods into the DC warehouse

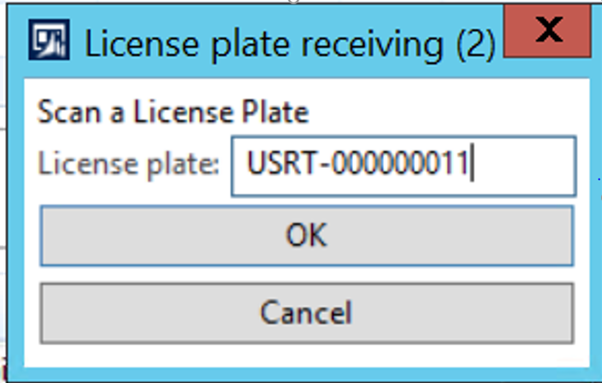

When the goods arrive at the DC, the mobile device operator first selects Inbound on the mobile device menu, and then selects LP receiving. He scans the parent LP.

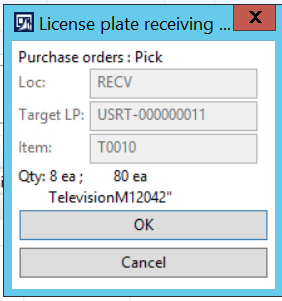

Details of the items expected to be received are displayed on the mobile device.

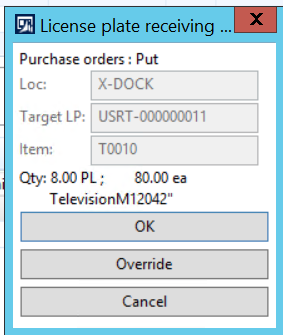

Once the receipt is confirmed, the operator is prompted to take these goods from the receiving bay

and put them in the X-DOCK location.

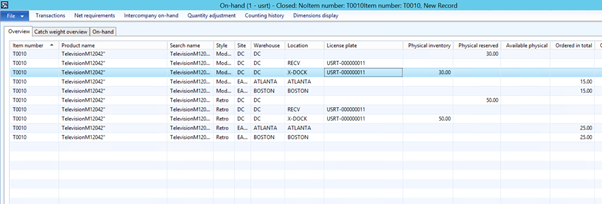

When the receipt has been completed, the On Hand stock enquiry shows that it has been received on the parent LP.

Assign a LP to each package

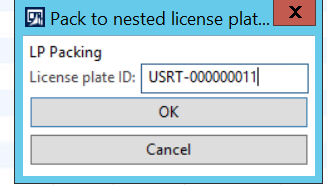

The last step in the receiving process is to run the LP Packing mobile device menu option. This will ‘move’ the stock from the parent LP to the nested LPs, assigning a LP to each carton.

The operator must select ‘LP Packing’ on the mobile device, and scan the parent LP.

After the LP Packing has been completed, the On-Hand stock shows no stock on the parent LP, and 5 Retro TVs and 3 Modern TVs on each ‘child’ LP.

Release the transfer orders for picking

At this point, the transfer orders can be released for picking. This can be done from the Periodic menu in Warehouse management.

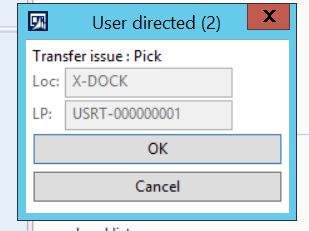

The next step to be taken depends on whether ‘Automatically process’ is enabled in the Transfer Issue work template. This may be the case if the outbound dock is designated as the cross-dock location where no staging area is required. In this case, the pick and put transactions are automatically completed, and the transfer order can be shipped immediately.

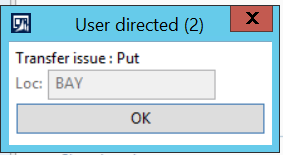

If ‘Automatically process’ is not enabled, the operator is prompted to pick each child LP and put the package in the bay.

Finally, the transfer orders can be shipped by confirming the loads, and the cross-docking process is completed.