How to configure Bulk items into a Formula for a Packed Item and have MRP generate Planned orders for both

I’ve recently worked with customers whom are attempting to create Bulk item conversions into the Formula configuration for a Packed Item and have MRP have the capability to generate Planned Orders for both the Pack and the Bulk Item. As a result of this, I’ve documented the overall setup\configuration, as an example, in order to accomplish this scenario. Please take a look at the following example\scenario assumed from a Dynamics AX 2012 R3 CU11 environment:

1. Login to USMF.

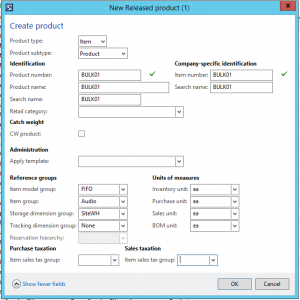

2. Create a new bulk item called BULK01 by taking the following steps:

a. Go to Product information management | Common | Released products.

b. From the Released products list page, click New | Product.

c. In the Create product form, enter the following:

Product type = Item

Product subtype = Product

Product number = BULK01

Product name = BULK01

Search name = BULK01

Item number = BULK01

Search name = BULK01

Item model group = FIFO

Item group = Audio

Storage dimension group = SiteWH

Tracking dimension group = None

Inventory unit = ea

Purchase unit = ea

Sales unit = ea

BOM unit = ea

d. Click OK out of the Create product form.

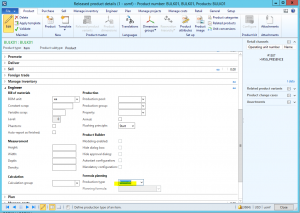

e. Back in the Released products list page, click on the BULK01 item, and then click Maintain | Edit.

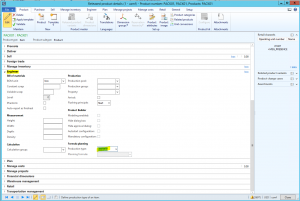

f. In the Released product details form, expand the Engineer fast tab, and select ‘Formula’ in the Production type field.

3. Configure a new formula for the BULK01 item by taking the following steps:

a. While still in the Released product details form, click the Engineer tab from the Action pane at the top, and then click Formula | Lines.

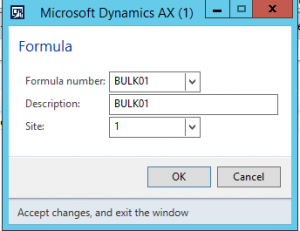

b. In the Formula line form, click the Create formula button.

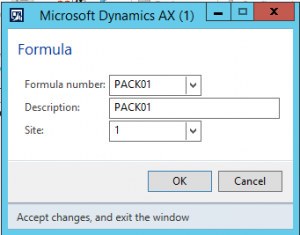

c. In the Formula form, enter the following, and then click OK:

Formula number = BULK01

Description = BULK01

Site = 1

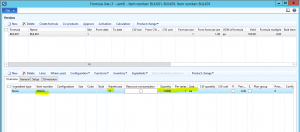

d. In the Formula line form, enter the following line:

Ingredient type = None

Item number = M9203

Warehouse = 11

Quantity = 1.0000

Per series = 1

Unit = ea

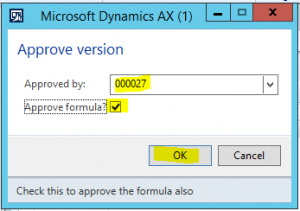

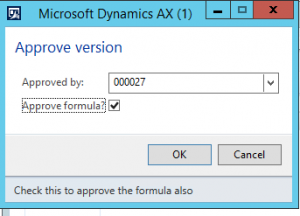

e. At the top of the Formula line form, click the Approve button.

f. In the Approve version pop-up form, enter the following, and then click OK:

Approved by = 000027

Approve formula = mark this checkbox

g. At the top of the Formula line form, click the Activation button.

h. Close the Formula line and Released product details forms.

4. Create a new packed item called PACK01 by taking the following steps:

a. Go to Product information management | Common | Released products.

b. From the Released products list page, click New | Product.

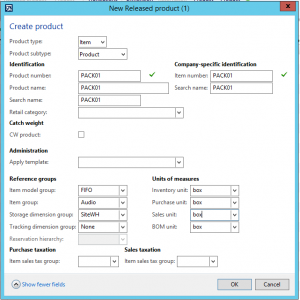

c. In the Create product form, enter the following:

Product type = Item

Product subtype = Product

Product number = PACK01

Product name = PACK01

Search name = PACK01

Item number = PACK01

Search name = PACK01

Item model group = FIFO

Item group = Audio

Storage dimension group = SiteWH

Tracking dimension group = None

Inventory unit = box

Purchase unit = box

Sales unit = box

BOM unit = box

d. Click OK out of the Create product form.

e. Back in the Released products list page, click on the PACK01 item, and then click Maintain | Edit.

f. In the Released product details form, expand the Engineer fast tab, and select ‘Formula’ in the Production type field.

g. Close the Released product details form.

5. Create a Bulk Conversion for the BULK01 item\PACK01 item by taking the following steps:

a. Go to Product information management | Common | Released products.

b. From the Released products list page, click on the BULK01 item, and then click Maintain | Edit.

c. At the top of the Released product details form, click the Manage inventory tab, and then click Packaging | Bulk item conversion.

d. In the Bulk item conversion form, enter the following line:

Packed product = PACK01

Factor = 10.00

Numerator = 1

Denominator = 1

Packed unit = box

Bulk item = BULK01

Bulk unit = ea

Rounding = To nearest

e. Close the Bulk item conversion form.

6. Create a new formula for the PACK01 item that has the BULK01 item as a Bulk item by taking the following steps:

a. Go to Product information management | Common | Released products.

b. From the Released products list page, click on the PACK01 item, and then click Maintain | Edit.

c. In the Released product details form, click the Engineer tab from the Action pane at the top, and then click Formula | Lines.

d. In the Formula line form, click the Create formula button.

e. In the Formula pop-up form, enter the following, and then click OK:

Formula number = PACK01

Description = PACK01

Site = 1

f. In the Formula line form, add the following line:

Ingredient type = None

Item number = BULK01

Warehouse = 11

Quantity = 10.00

Per series = 1

Unit = ea

g. At the top of the Formula line form, select ‘BULK01’ in the Bulk item field.

h. At the top of the Formula line form, click the Approve button.

i. In the Approve version pop-up form, enter the following, and then click OK:

Approved by = 000027

Approve formula = mark this checkbox

j. In the Formula line form, click the Activation button.

k. Close the Formula line and Released product details forms.

7. Create a new Sales order for the PACK01 item by taking the following steps:

a. Go to Accounts receivable | Common | Sales orders | All sales orders.

b. From the All sales orders list page, click New | Sales order.

c. In the Create sales order form, select ‘US-003’ from the Customer account drop-down field.

d. In the Create sales order form, expand the General fast tab, and select ‘1’ in the Site field, and ‘11’ in the Warehouse field.

e. Click OK out of the Create sales order form.

f. In the Sales order form, enter the following line:

Item number = PACK01

Quantity = 1.00

Unit = box

Site = 1

Warehouse = 11

Unit price = 1.00

g. Save the sales order.

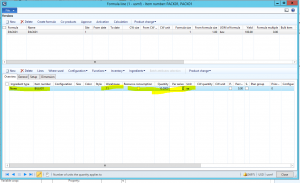

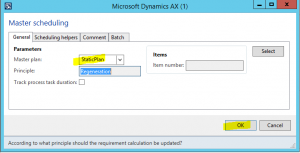

8. Run MRP to create Planned Batch orders for the BULK01\PACK01 items by taking the following steps:

a. Go to Master planning | Periodic | Master scheduling.

b. In the Master scheduling form, select ‘StaticPlan’ from the Master plan field, and then click OK.

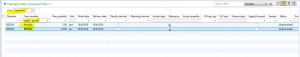

At this point in time, you will see that you have a Planned Batch Order for the BULK01 Item and also a Planned Batch Order for the PACK01 Item. These Planned Batch Orders can be then consolidated and grouped together and eventually firmed into actual Batch Orders.