Automatic and manual item reallocation during short picking – Dynamics 365 for Operations (1611)

Introduction

In Microsoft Dynamics AX 2012 R3 you could short pick an item while executing the initial picking of an outbound work line using a mobile device. One of the challenges with that design is that after short picking, it was difficult to easily identify an alternative item location. This meant for the short-picked quantities to be part of the re-waving process, there needed to be additional processing time or goods were not always shipped in full, even if the alternative location had available items. With this new feature, we have designed both an automatic and manual feature for the warehouse user so that the user can select alternative locations (automatic) or select any location that has available inventory for that item (manual). This functionality is available in Dynamics 365 for Operations (1611).

You can set up the short picking work exception to do automatic, manual, or automatic and manual reallocation. These are the different options:

- Automatic reallocation – The location directives for the related work order type and warehouse will be queried. If there is available on-hand quantity at another location, the work will be updated and the user will be directed to pick the remaining items from the new location.

- Manual reallocation – A list with all the locations with unreserved quantity of that item will be displayed. The warehouse user can select one or more locations.

- Automatic and manual reallocation – The system will first try to automatically reallocate the quantity and if this is not possible, the warehouse user will see a list of locations. The location directives will not be queried and any location with available on-hand quantity will be displayed in the list.

Setup

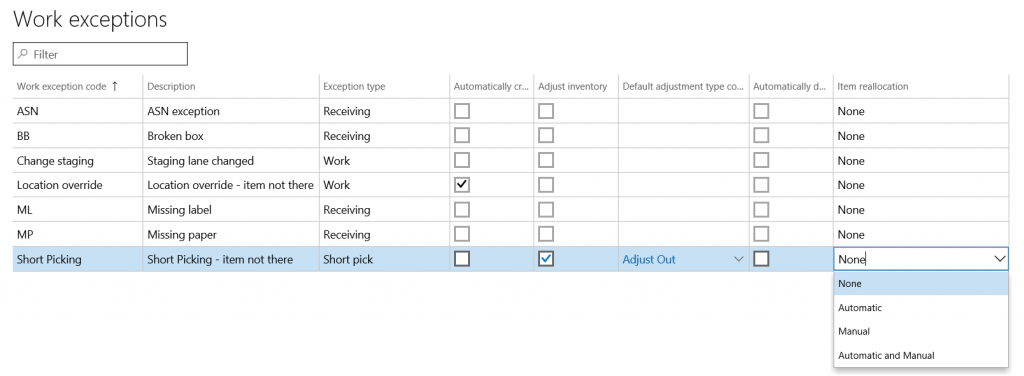

Work exceptions page

Item reallocation dropdown

You can select the Item reallocation option on the Work exceptions page. This allows you to define several work exceptions with different item reallocation policies, so that the warehouse worker can choose one policy based on the guidance or on the needs of the shipment that he is processing.

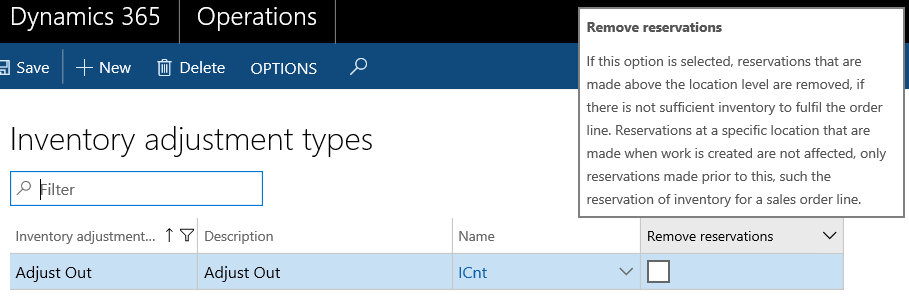

Adjust inventory and adjustment type

Note, if the Adjust Inventory option is selected, all quantity for that the location and the dimensions above the item that is being short picked will be adjusted. This does not apply to items with tracking dimensions that are below the location.

You can also specify if you want to remove reservations.

Let’s say that there are 10 chairs available in your warehouse, all in one location and on one license plate. You release a sales order to pick all the 10 items from this location, and then set the work exception to adjust the inventory. When the warehouse user does short picking and only picks 2 chairs, the process might fail. To avoid this, select Remove reservations, so that the sales line reservation has a reservation on the 8 pieces and this reservation needs to be removed. Otherwise it is not possible to proceed, because the system cannot keep this reservation.

However, there can be other license plates at the same location or other locations that have 8 or more pieces available. In that case, regardless if Remove reservations is selected, the short picking will be completed sucessfully and the sales order line reservation for all the 10 pieces will be kept.

Note, the Remove reservations option does not apply to work reservations. Existing work reservations from the same orders or from other orders will be kept.

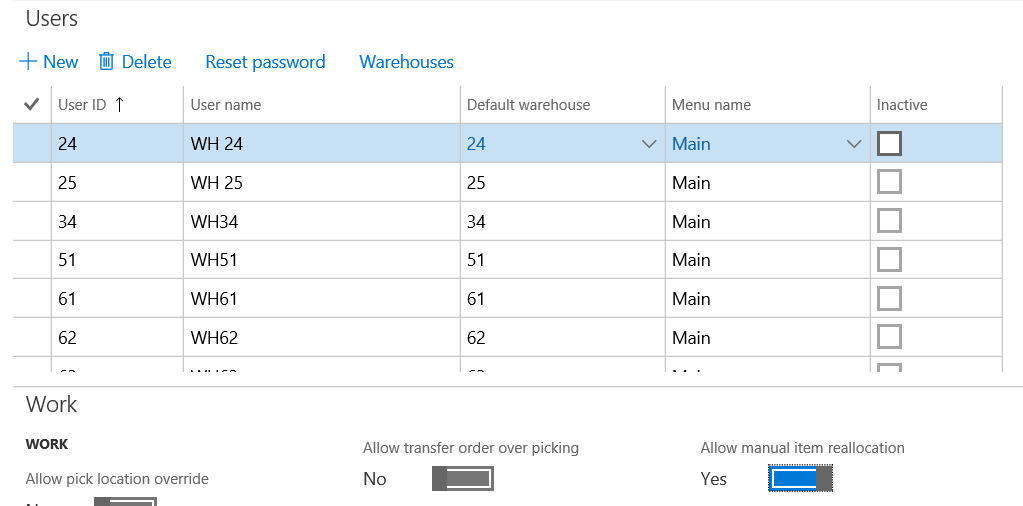

Work user page

Automatic reallocation is available for all users, while manual reallocation requires explicit setup for the user. This is because the visibility given to each user may be different because the items may be in a quarantine area or in a bulk area in which only trusted employees have access.

If a reallocation process has been selected, but the user is not eligible to use this process, a message will be added in the work creation history log and the user can continue to process the work as usual. Every time that the warehouse user selects an exception, a message will be added in the history log. The user will not receive any further information on his mobile device.

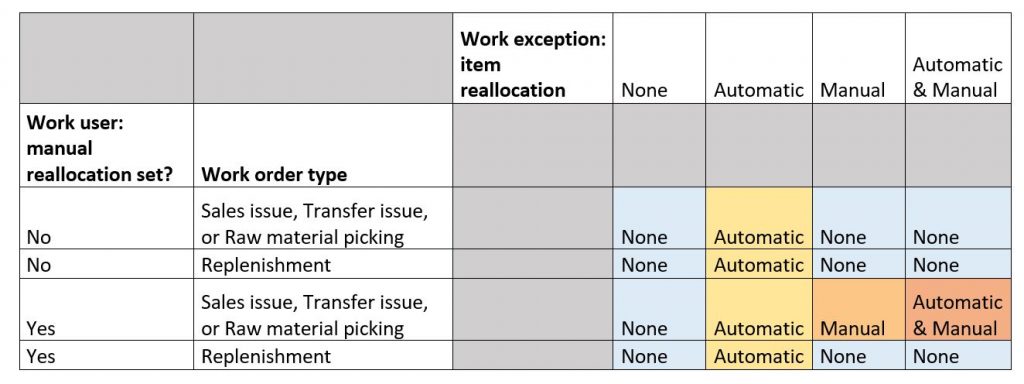

Supported work order types

All work order types that currently support short picking have been enabled for automatic reallocation: sales issue, transfer issue, raw material picking, and replenishment.

Note, if a replenishment line gets partially reallocated, the demand sales work (if any) will be updated accordingly. Moreover, replenishment links will be created (records in the WHSReplenWorkLink table) to point to the reallocated work lines.

Replenishment has been disabled for the manual reallocation, but all the other work order types are available for this process. In the following matrix, you can see which reallocation process will be triggered (if any), based on the work exception and work user setup. For example, if manual reallocation is not set for the warehouse user, the order type of the work being processed is Replenishment (3rd row of the matrix). The selected work exception has Item reallocation set to be automatic (5th column of the matrix), then the automatic reallocation process will be triggered.

General

Automatic reallocation

If the user selects a work exception with automatic item reallocation enabled, when he short picks a work line, he will receive a short pick confirmation screen after he enters the quantity that he wants to pick. After he confirms the short picking, the system will run through the location directives that have been defined for the specific order type and warehouse, and try to find one or more locations to pick the remaining quantity from. If only part of the quantity remaining to be picked is available in another location, only that quantity will be reallocated. If the location directive line has been set up to allow a split, more than one location can be selected to reallocate the quantity from.

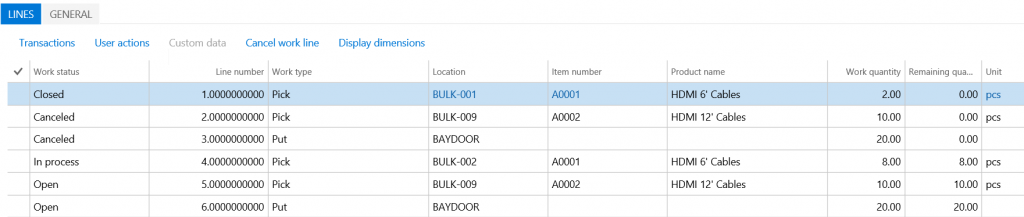

The work will be updated accordingly. The following is an example of the work lines before and after the reallocation has been executed. The work lines show before item A0001 was short picked from location BULK-001.

This is what it looks like when work lines after item A0001 are short picked and the system reallocates 8 pieces from location BULK-002.

As you can see, all the work lines that were open or skipped when a line was short picked (in this case lines 2 and 3) are canceled and recreated after the reallocated work lines. This is necessary in order to maintain the correct sequencing of the work lines.

Manual reallocation

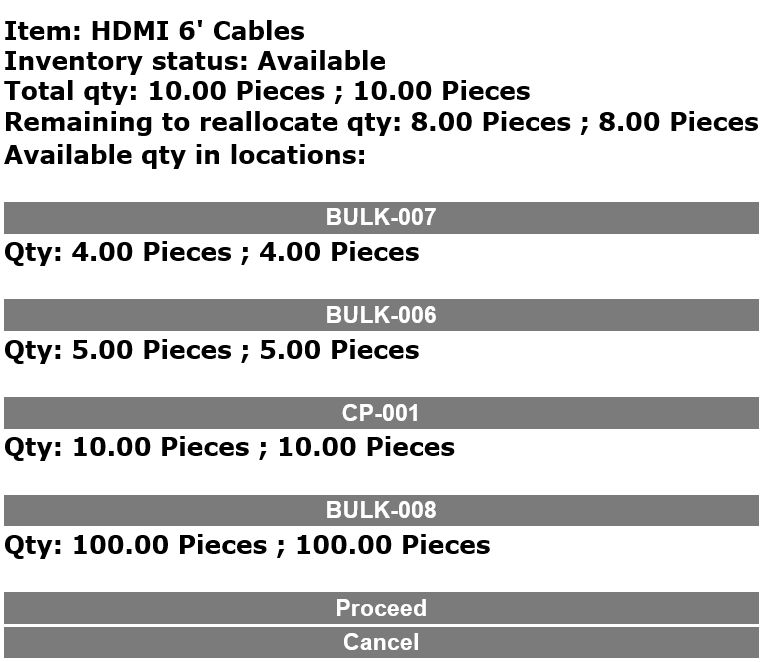

If the user selects a work exception with the manual item reallocation, he will see a list with all the locations of the same warehouse that have available quantity to create work. The short pick confirmation will not be displayed. The short picking will be executed after the user either selects a location or clicks Proceed in the first manual reallocation list. The locations will be sorted by available quantity in ascending order.

If the user clicks Proceed, the short picking will be executed and no quantity will be reallocated. If the user selects a location ID, for example BULK-007, the short picking will be executed and a new work line will be created to pick 4 pieces from BULK-007. This will display the following list.

If the user clicks BULK-006, the work will be updated again and one more pick work line will be created with 4 pieces from BULK-006. If all the quantity has been reallocated or if there are no other locations with available on-hand quantity, the user will proceed with processing the work. All locations will be displayed, regardless of the location directives.

The maximum number of locations to be displayed in the list is 120. If you need to display more locations, you can update the SessionSchema.xsd file in the WMDP solution to have a higher number of the controls. The current number is set to 250 (“maxOccurs = 250”) and each location displayed in the list needs two controls.

Automatic and manual reallocation

For automatic and manual reallocation, after the user has entered the quantity that he is short picking, the system will check if all the remaining quantity can be automatically reallocated. If it can, the short picking will be confirmed and the automatic reallocation will be executed. If none or only part of the quantity can be automatically reallocated, this process will be skipped and manual reallocation will be triggered.

Work creation history log

In all the above scenarios, there might be a delay between the short picking and the automatic or manual reallocation, which can result in other orders reserving inventory that had been initially calculated to be available for the reallocation. If that occurs, the quantity that will be finally reallocated will be available. If it is less than what was shown to the user, a message will be added in the work creation history log. The quantity that was not reallocated will be short picked and will need to be waved again.

Conclusion

You can use item reallocation during short picking to pick the entire quantity for a work order. The on-hand quantity registered in the system can be out of sync or for some reason it might not be possible to pick some items that are registered in the initial location. The warehouse user now has additional capabilities to partially or fully fulfill the customer request. The customer request can be fulfilled faster and it will be no longer necessary to create a new wave and release new work to fulfill the demand.

Additional ideas for further enhancing this feature include:

- Providing the warehouse manager with the ability to define a list of location profiles that should be excluded from the manual reallocation list.

- Enabling manual reallocation for replenishment order types.

We would appreciate your feedback on the above suggestions.