Transforming Supply Chains: Exploring Advanced AI-Powered Demand Forecasting and Demand Planning in Dynamics 365 Supply Chain Management

Introduction:

In the ever-changing landscape of contemporary business, effective supply chain management is paramount. Central to this complex system is the critical process of demand planning and forecasting, which profoundly impacts a company’s capacity to fulfil customer requirements, optimize inventory, and maintain a competitive edge. This article explores the significance of demand forecasting and how Microsoft seamlessly incorporates it into its new demand planning in Dynamics 365 Supply Chain Management.

The Crucial Role of Demand Planning and Forecasting:

Precise demand planning and forecasting play a pivotal role in diverse facets of business operations, yielding advantages throughout the entire supply chain:

- Accurate Inventory Management: Precise demand forecasting optimizes inventory levels, finding the balance between excess stock and stockouts.

- Customer Satisfaction: Accurate forecasting ensures products are available in the right place at the right time, enhancing customer satisfaction and brand loyalty.

- Cost Reduction: Effective demand forecasting minimizes holding costs for excess inventory and reduces costs associated with stockouts.

- Resource Allocation: Anticipating demand aids in efficiently allocating resources, including labor, production capacity, and raw materials.

- Improved Collaboration: Accurate forecasting fosters collaboration across the supply chain, enhancing coordination between suppliers, manufacturers, and retailers.

- Long-term Planning: Strategic planning benefits from accurate forecasting, aiding businesses in adapting to changing market conditions and trends.

- Competitive Advantage: Organizations responding effectively to market changes gain a competitive edge.

Exploring a Range of Demand Forecasting Models:

Below is a concise examination of diverse forecasting models employed in general Supply Chain demand planning, accompanied by insights into their potential applications within a business context.

- Qualitative Forecasting:

- Delphi Method: In the tech industry, when forecasting the demand for a new product, experts from different fields like engineering, marketing, and finance may anonymously provide input through multiple rounds of questionnaires.

- Market Research: A smartphone company might conduct extensive market research, including customer surveys and competitor analysis, to forecast demand for its next flagship device.

- Time Series Analysis:

- Prophet: In the retail sector, employ Prophet time series analysis for precise demand forecasting, enabling efficient inventory management, minimizing stockouts, and maximizing profitability.

- Exponential Smoothing: A fashion retailer might use exponential smoothing to predict future sales based on the recent trend in sales for specific clothing items.

- ARIMA: A beverage company could apply ARIMA models to forecast demand for a seasonal drinks during holidays.

- Best Fit: In healthcare, ‘Best Fit’ involves selecting the optimum statistical model to capture dataset patterns. Applying best-fit time series analysis anticipates patient needs, optimizes resource management, and enhances operational effectiveness for improved outcomes and satisfaction.”

- ETS (Error-Trend-Seasonality): Hospitality and Tourism, utilize ETS models to forecast hotel bookings and tourism trends, enabling businesses to optimize pricing strategies and allocate resources efficiently based on seasonal fluctuations.

- Causal Models:

- Regression Analysis: An automobile manufacturer might use regression analysis to predict the impact of advertising spending on the demand for a particular car model.

- Econometric Models: In the energy sector, econometric models could be employed to forecast electricity demand based on economic indicators such as GDP and population growth.

- Machine Learning Models:

- Neural Networks: An e-commerce platform might use neural networks to predict customer demand for various products by considering factors like browsing history, purchase patterns, and customer demographics.

- Random Forest: A retail chain could employ a random forest model to forecast the demand for different product categories based on historical sales data and external factors like economic trends.

- Judgmental Forecasting:

- Expert Input: In the pharmaceutical industry, stakeholders may provide expert opinions to forecast the demand for a new medication, considering factors like regulatory approval, market acceptance, and healthcare trends.

These forecasting models offer diverse approaches, catering to various industries and scenarios.

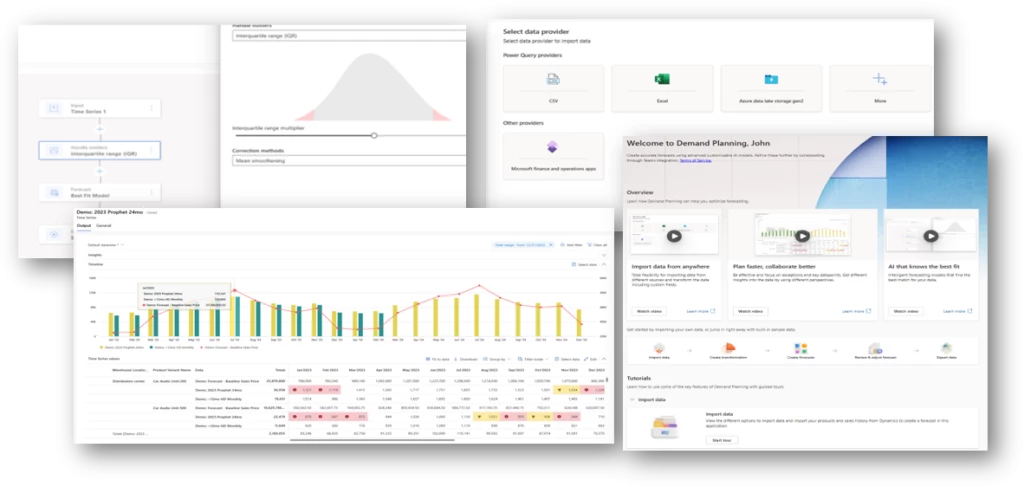

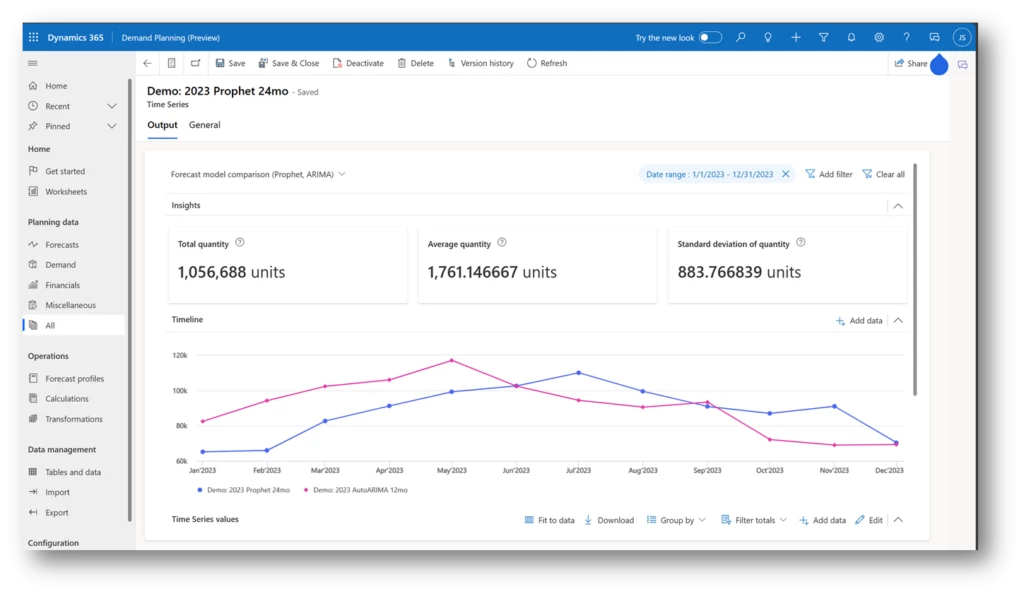

Demand forecasting in Dynamics 365 Supply Chain Management

In the context of demand planning in Dynamics 365 Supply Chain Management, the efficiency of demand forecasting is bolstered by a robust suite of features. The system taps into the potential of built-in out-of-the-box AI-powered algorithms, integrates existing models, utilizes the capabilities of Custom Azure Machine Learning (AML), advanced forecasting models, forecasting profiles, and streamlined data hierarchy management to enhance the precision of demand planning. Through the seamless integration of these elements, the platform guarantees the accuracy of demand forecasts, facilitates the smooth identification and handling of outliers, and adeptly oversees various facets of the supply chain.

Built-in AI Algorithms:

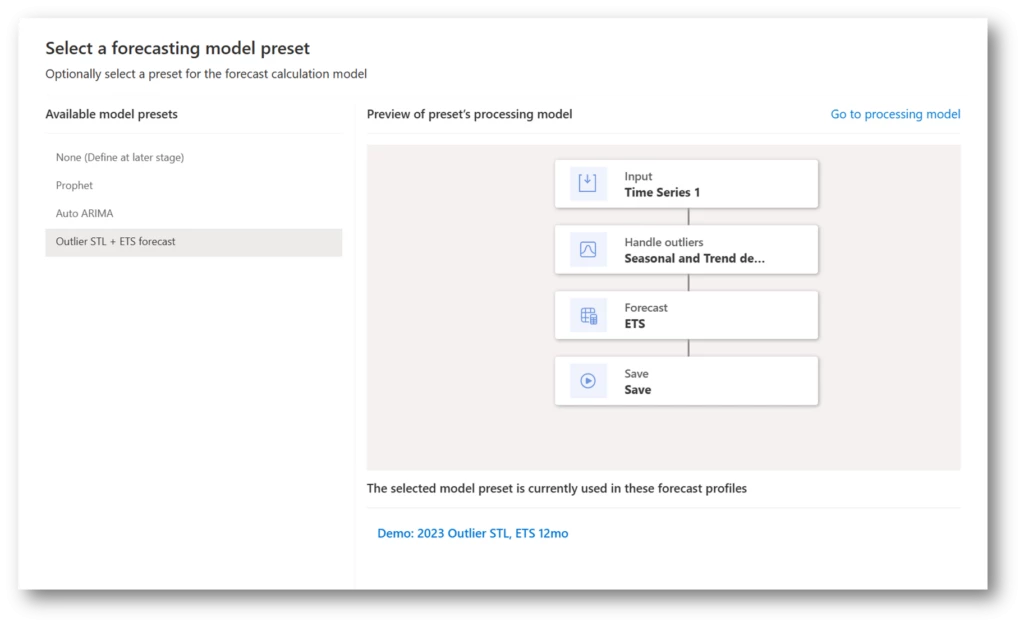

Access to pre-configured and out-of-the-box AI-based models like Arima Prophet, ETS, and outlier removal without the need for additional configuration provides users with a powerful and user-friendly forecasting solution. This feature enables businesses to quickly leverage advanced forecasting techniques, enhancing the accuracy of predictions.

Advanced Forecasting Models:

The platform supports advanced forecasting methods such as ARIMA, ETS (Error-Trend-Seasonality), Prophet, and Best fit, ensuring a high degree of accuracy in demand forecasts. Leveraging the capabilities of custom Azure Machine Learning (AML), this flexibility empowers businesses to customize their forecasting strategies based on the distinct characteristics of their products and the dynamics of their market.

Use your own Forecast Models

If you’ve created your own forecasting models or utilize Azure Machine Learning within Dynamics 365 Supply Chain Management, you can leverage the collaborative editing features within the app to directly invoke your custom models. This allows you to seamlessly integrate your pre-built models alongside the out-of-the-box models provided, tailoring your forecast for optimal accuracy.

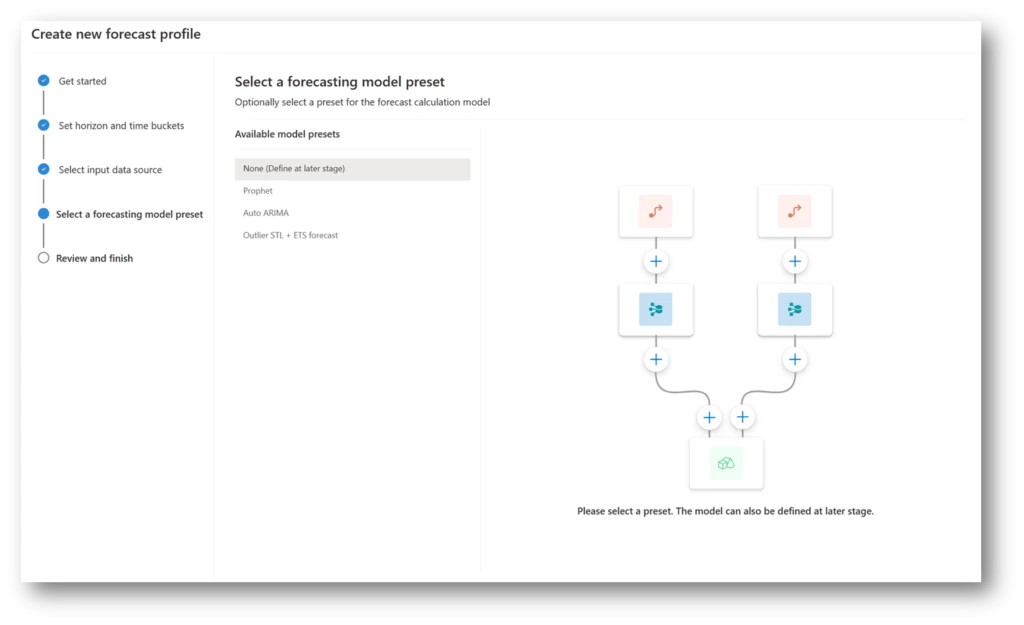

Forecasting Profiles:

Users can craft and manage forecasting profiles, streamlining calculations and facilitating the application of outlier removal techniques. This feature adds a layer of customization to the forecasting process, allowing organizations to adapt to specific business requirements and scenarios.

Outlier Detection and Removal/Handiling:

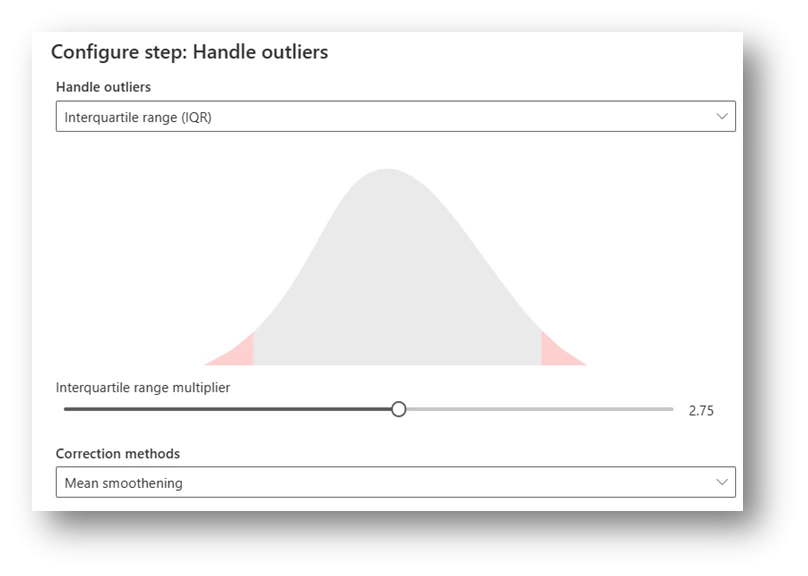

Detecting outliers in demand planning is a vital component of forecasting and supply chain management. The identification of outliers plays a key role in enhancing the precision of demand forecasts and ensuring the appropriate handling of anomalies. This process is streamlined through the intuitive Outlier Detection capabilities embedded in demand planning within Dynamics Supply Chain Management.Detecting and eliminating outliers is a pivotal stage in data preprocessing, essential for enhancing the accuracy and dependability of statistical analyses and machine learning models. Employ advanced methods, particularly the Interquartile Range (IQR) and Seasonal-Trend Decomposition using LOESS (STL), to skillfully pinpoint and preemptively manage outliers. This strategic approach contributes to improved precision and effectiveness in data analysis.

Outlier Removal/Handling Techniques:

- Leverage sophisticated approaches, notably the Interquartile Range (IQR) and Seasonal-Trend Decomposition using LOESS (STL), to adeptly identify and proactively address outliers for enhanced precision and effectiveness in data analysis.

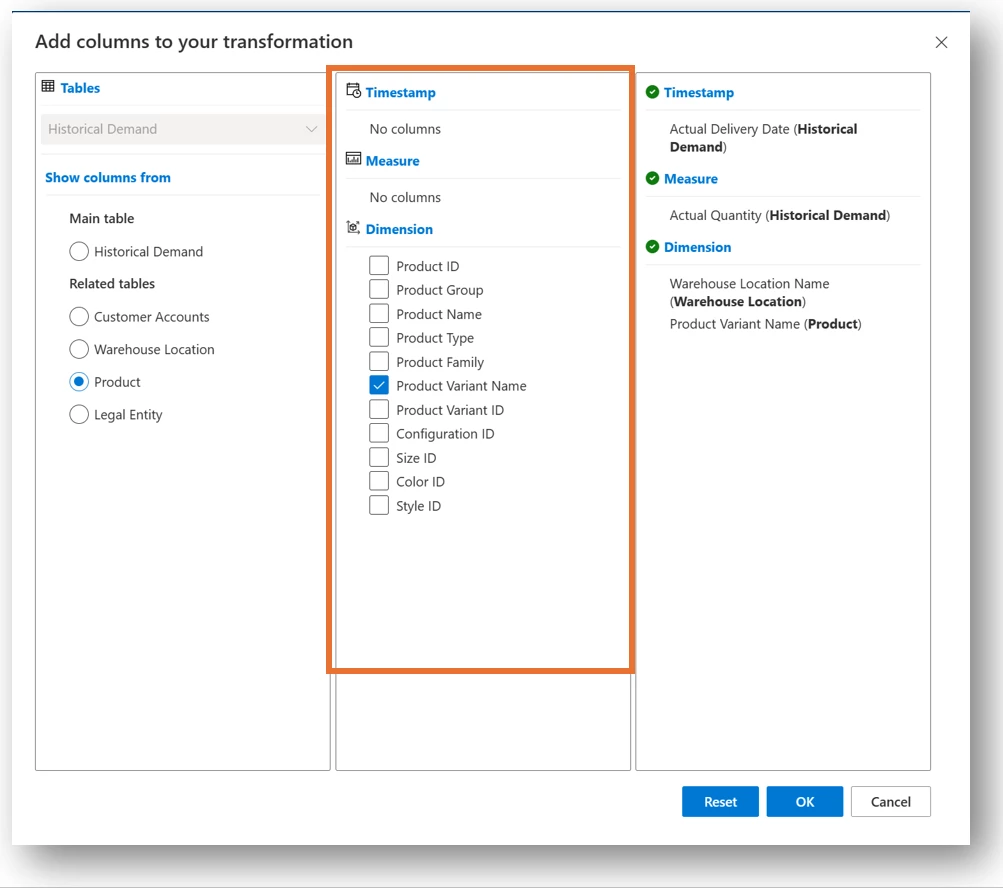

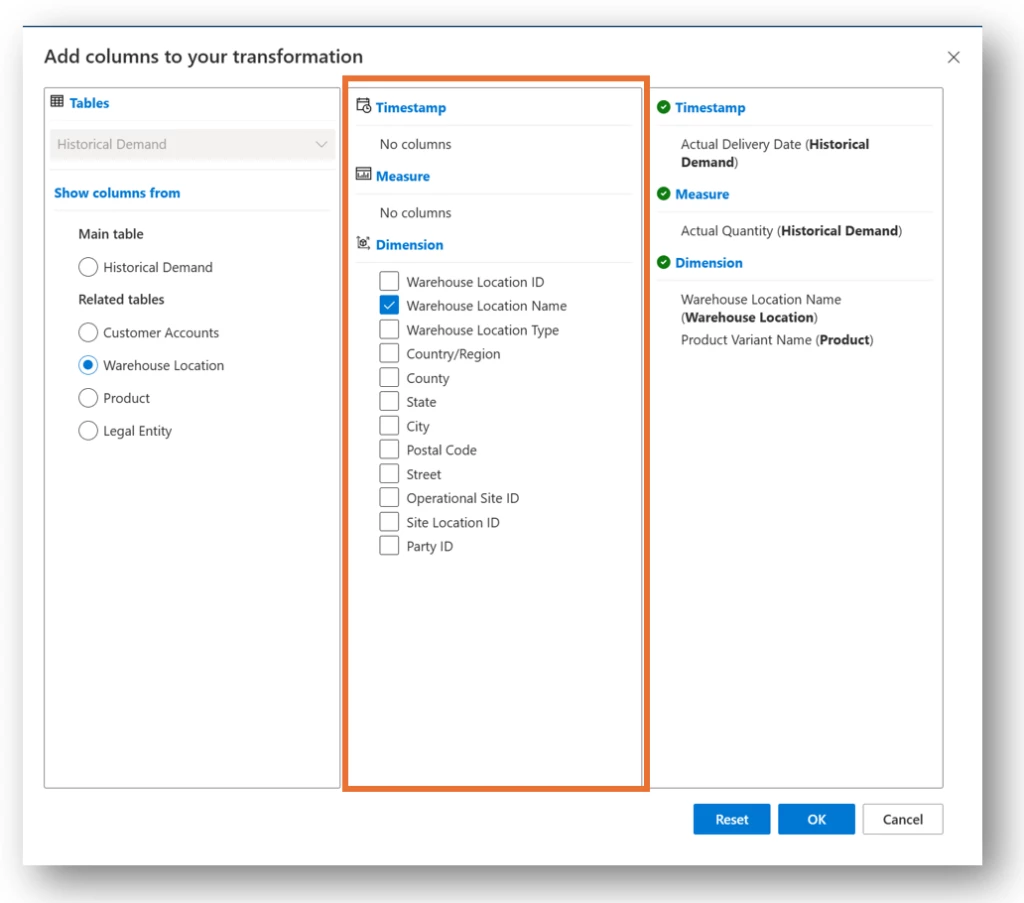

Data Hierarchy Management:

Efficient data hierarchy management is crucial for granular forecasting and optimizing supply chain operations. Demand planning in Microsoft Dynamics 365 Supply Chain Management provides comprehensive hierarchy management across products, locations, and time:

- Product Hierarchy: A retail electronics company organizes its product catalog with a hierarchical structure, starting broadly with categories like smartphones and laptops and becoming more granular with specific brands and models. This detailed hierarchy enables the company to forecast demand patterns at a specific product level, enhancing inventory management.

- Location Hierarchy: The company optimizes distribution based on a location hierarchy that spans global, regional, and local levels. Understanding variations in demand by region helps in strategic decision-making for supply chain management, ensuring efficient allocation of inventory to meet the unique demands of each location.

- Time Hierarchy: Capturing seasonality and trends through time hierarchy management, the company analyzes daily, weekly, monthly, and yearly variations in demand. This temporal sensitivity enhances the accuracy of predictions, allowing the business to adjust inventory levels and marketing strategies to meet fluctuating consumer preferences throughout the year.

Enhanced Integration with data:

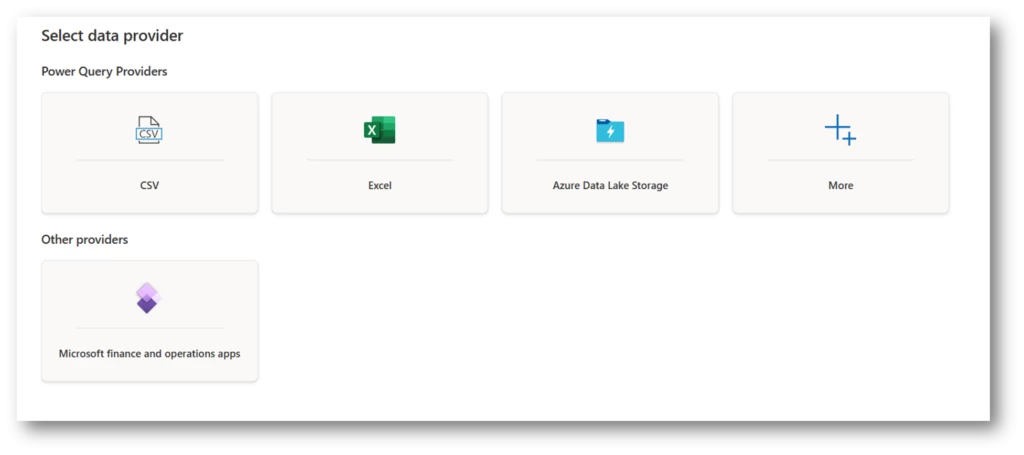

Demand planning in Dynamics 365 Supply Chain Management seamlessly integrates your data, further enhancing the capabilities of the demand forecasting solution:

Virtual Entities:

The platform supports the extension or creation of custom entities within Microsoft Finance and Operations, enabling integration with additional data sources. This flexibility ensures that businesses can incorporate diverse datasets into their demand forecasting models.

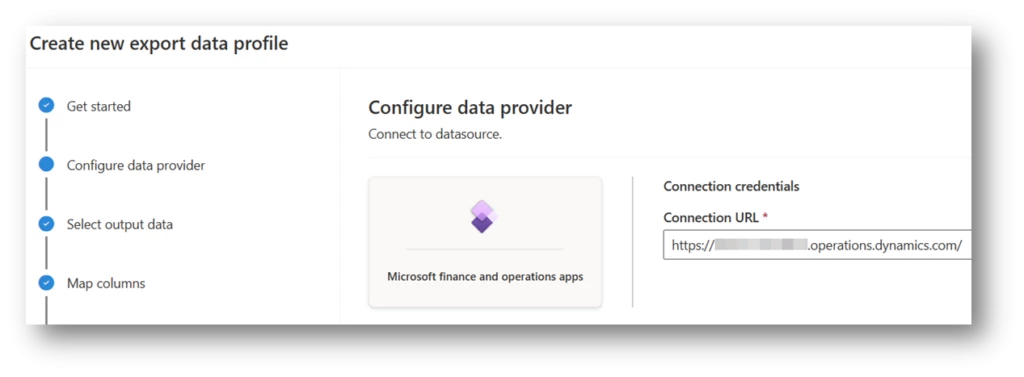

Finance and Operations Integration:

The smooth export of planned data back into Microsoft Finance and Operations marks the culmination of the supply chain planning cycle. This closed-loop integration guarantees that the generated demand forecasts are directly incorporated into the broader finance and operations context, promoting consistency and accuracy throughout the organization. Users have the flexibility to plan across various instances of Dynamics 365 Finance and Operations at a higher level and selectively export specific parts of the plan to designated locations.

Azure Data Explorer (ADX):

Efficient data storage, aggregation, and disaggregation in Azure Data Explorer optimize performance. This integration allows businesses to harness the power of Azure’s data capabilities for more robust forecasting and analytics.

Conclusion:

Microsoft Dynamics 365 Supply Chain Management’s demand planning feature provides a comprehensive solution for demand forecasting. This solution incorporates outlier detection, advanced forecasting models, seasonality analysis, and robust scenario planning capabilities. The integrated approach enables businesses to make well-informed decisions, adapt to changing conditions, and maintain a competitive edge in a dynamic market environment. Demand planning and forecasting are crucial aspects of effective supply chain management, enhancing agility, responsiveness, and competitiveness in today’s dynamic marketplace.

The article explores various forecasting models and demonstrates their real-world applications. Dynamics 365’s features, such as built-in AI algorithms, advanced forecasting models, forecasting profiles, outlier detection, and data hierarchy management, are highlighted as key elements that improve accuracy.

Additionally, the platform’s integration capabilities with Azure Data Explorer and Dynamics 365 Supply Chain Management are emphasized, creating a closed-loop system that optimizes forecasting accuracy and extends its impact across the organization.

To navigate the complexities of supply chain management, businesses can strategically leverage Dynamics 365 Supply Chain Management. This proactive approach allows them to adapt to future challenges, gain a competitive edge, and foster sustained success in the ever-evolving landscape of modern business.

Learn More

Access the demand planning solution, Documentation, and Workshop:

To access the demand planning Application and learn more about its features, follow the provided links. Additionally, don’t miss the upcoming demand planning workshop in Denmark to dive deeper into this transformative tool.

Access the demand planning in Dynamics 365 Supply Chain Management:

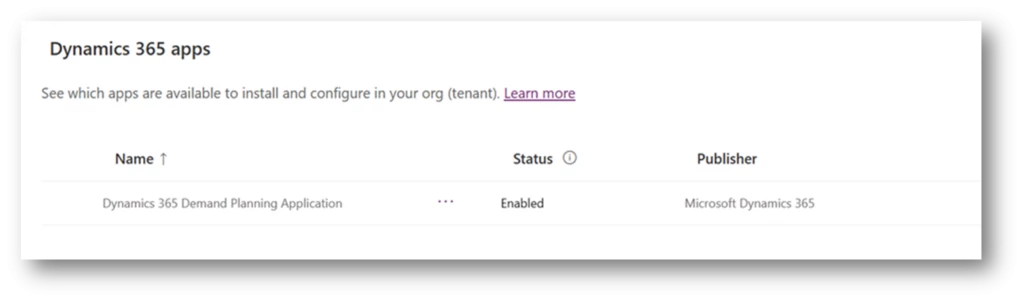

To install the latest version of the demand planning application, ensure that you are using Dynamics 365 Supply Chain Management, and then visit the Power Platform Admin Center. Search for the Dynamics 365 demand planning Application and follow the installation process.

Click here to access: Demand planning in Dynamics 365 Supply Chain Management

Demand planning Documentation:

If you’re interested in learning more about our demand planning Application, we’ve prepared an extensive collection of highly informative documents for your review and easy access.

You can find them right here: Demand planning Documentation

Demand planning – Demonstration Videos:

We’ve taken extra steps to create a series of informative demo videos that will not only guide you through the application but also showcase a multitude of features available in the demand planning Application.

Demand Planning Insights Videos:

Meet the Team: Onsite Workshop December 2023

The forthcoming demand planning Workshop, to be held at Microsoft’s facility in Lyngby, Denmark, is geared towards introducing the new demand planning application to both Customers and Partners. Furthermore, it will provide an in-depth exploration of the product’s features and capabilities.

The workshop will also cover various important topics, including:

- Exploring the contents of the Public Preview October 21st and December update.

- Engaging hands-on lab activities.

- Participating in a user experience (UX) study or exercise.

- Understanding how these developments align with the broader context of Supply Chain Planning.

- An overview of Copilot for demand planning.

- Customer insights and feedback.

Please note that a more detailed agenda will be provided to attendees as the workshop date approaches.

Date: 4th+ 5th December 2023

Duration: 2 days

Location: Lyngby, Denmark

Demand Planning Community – Yammer

Join our Yammer group to stay updated with monthly evaluations, scripts, and videos related to the demand Planning Application. Your journey to supply chain transformation begins here.