Return material adjustment (RMA) processing through the mobile device

This blog post assumes a working knowledge of the new

Warehouse management module released in Microsoft Dynamics AX 2012 R3.

The process of receiving a Return material adjust (RMA)

using the new WMS mobile device functionality is very similar to processing an

inbound transaction such as a purchase order. The following steps are intended

as a walkthrough of the necessary setup and actions required to complete the

process. They are completed against the USMF Contoso dataset on a CU8 installation.

1)

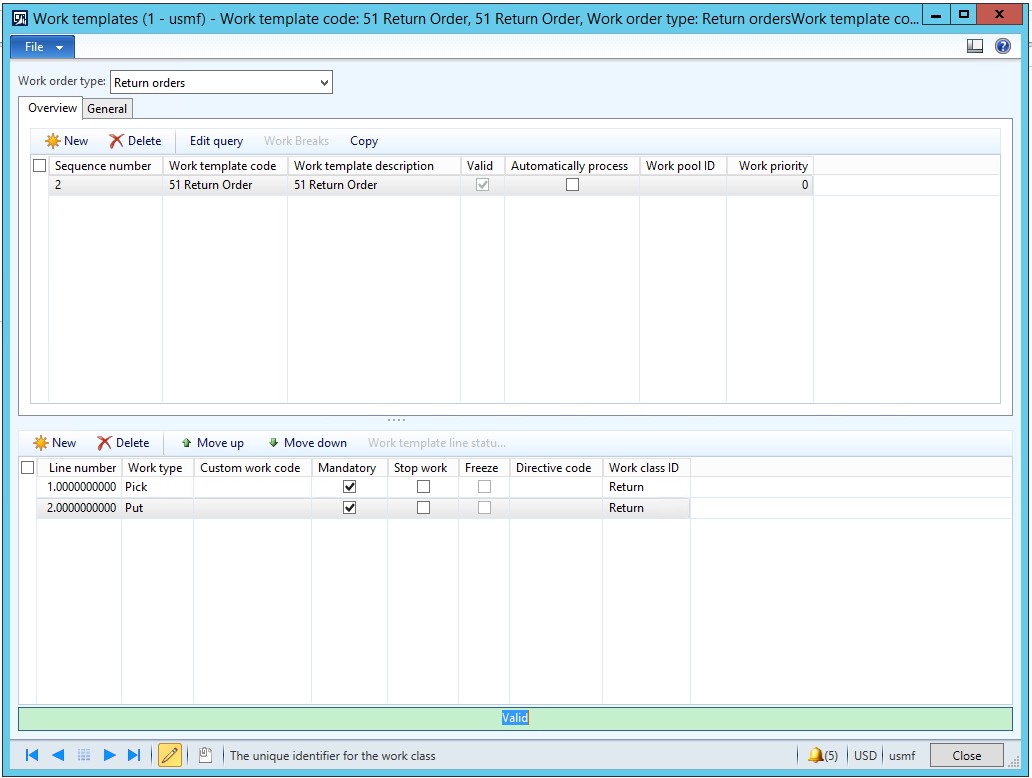

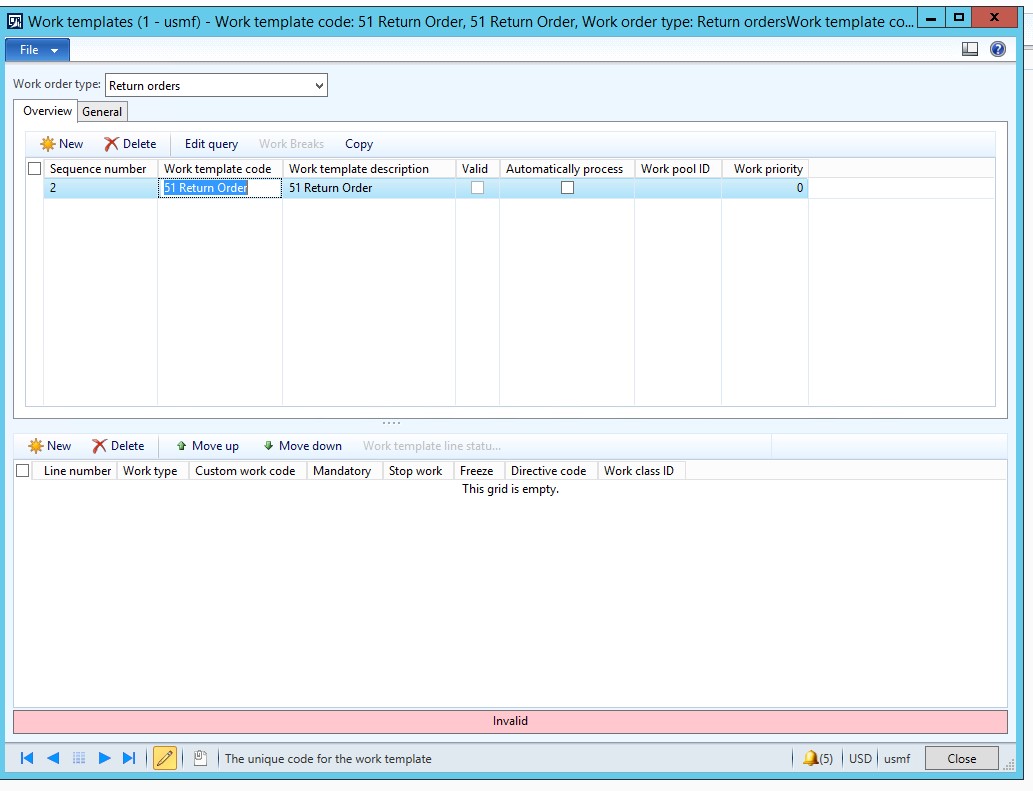

Setup a Return order work template

- Warehouse > Work > Work Templates

- Change the Work order type to “Return orders”

- Create a new work template by clicking the New

- Create new work type lines by clicking the New

button on the low section of the grid - Create two lines

i.

The first

ii.

Work type = Pick

iii.

Mandatory = Checked

iv.

Work class ID = Return

v.

The second

vi.

Work type = Put

vii.

Mandatory = Checked

viii.

Work class ID = Return

ix.

Close the form

2)

Setup a Disposition code and link it to an

inventory status

- Warehouse management > Mobile device >

Disposition codes - Create a new Disposition code by clicking the

New button - The new Disposition code will need the following

fields

i.

Disposition code: The name of the disposition

code.

ii.

Inventory status: An inventory status which will

define the blocking strategy assigned to the returned item.

iii.

Work template code: The work template to which

this disposition code should be linked.

iv.

Return disposition code: A traditional

disposition code that contains the disposition action.

- *Note*: Any disposition code that has an action

of “Return to customer” will not generate work as of CU8 - Create the record with the following values

i.

Disposition code = Customer return

ii.

Inventory status = Available

iii.

Work template code = 51 Return Order

iv.

Return disposition code = 11

v.

Close the form

3)

Create a location directive to manage the Return

order process in the warehouse

- Warehouse management > Setup > Location

directives - Change work order type to “Return orders”

- In the Location directives fast tab click New

i.

Sequence number = 1

ii.

Name = 51

iii.

Work type = Put

iv.

Site = 5

v.

Warehouse = 51

vi.

Disposition code = Customer return (the

disposition code must be specified or the location directive will not be

found).

- In the Lines fast tab click New

i.

Sequence number = 1

ii.

From quantity = 1

iii.

To quantity = 999,999

iv.

Locate quantity = None

- In the Location Directives Actions Click New

i.

Sequence number = 1

ii.

Name = Put

iii.

Fixed location usage = Fixed and non-fixed

locations

iv.

Strategy = None

- In the Location Directive Actions fast tab click

Edit Query - Set the Location Criteria = Bulk-001

- Click OK to close the form

- Close the Location directives form

4)

Create a menu item on the Mobile device

- Warehouse management > Setup > Mobile

device > Mobile device menu items - Click New to create a new menu item

i.

Menu item name = RMA Process

ii.

Title = RMA Process

iii.

Mode = Work

iv.

Work creation process = Return order receiving

v.

Close the form

5)

Add the new mobile device menu item to the

mobile device

- Warehouse management > Setup > Mobile

device menu - In the Available menus and menu items section

find the RMA process and add it to the menu structure by clicking the “<”

button

6)

Create a return order

- Sales and marketing > Common > Return

orders > All return orders - In the panel click Return orders> New >

Return order

i.

Customer account = US-004

ii.

Click OK to create the return orders

- Add a line to the return order

i.

Item number = A0001

ii.

Site = 5

iii.

Warehouse = 51

iv.

Unit price = 5

v.

Quantity = -1

vi.

Copy the RMA number on the Return order header

(General fast tab)

7)

Open the Emulator in the AOT and receive the RMA

to create the work

- AOT > FORMS > WHSWorkExecute > Right

click > Open

i.

User ID: = 51

ii.

Password = 1

- In the main menu select RMA Process

- Enter the RMA number click OK

- Item = A0001

- LP = TestLp

- Qty = 1

- Disposition code = Customer return

- Click OK

8)

Navigate back to the Return order and open the

sales order to view the work

- On the RMA select the sales order number to open

the sales order for the RMA

- On the Sales order in the Sales order lines

section click Warehouse > Work details - Notice

the work has been created. The pick in the receipt location and the put away is

set to the location specified in the location directive